What are the responsibilities of the supply chain function and what does that mean for our company?

Dan Key: Our centralized supply chain is responsible for ultimately supplying all of our products to our customers. Specifically, this includes the procurement of direct and indirect materials for the Company, supply and demand planning for our inventory, product manufacturing, storage and finally shipment to our customers. The supply chain function is also responsible for the maintenance of many of our facilities and our overall Environmental, Health and Safety programs that protect our employees from injury in the workplace.

Could you share some milestones that your team has reached since the beginning of the new year?

DK: As an organization, we are fortunate to have an incredibly talented and great Operations Leadership team in place. Supported by Mike Leggett, Vice President Supply Chain Planning, and Joanne Couture, Vice President of Global Procurement, the team is working hard and has already reached quite a number of milestones this year. These include the completion of the new centralized organization for supply chain, the establishment of Sales and Operations Planning process, and the completion of necessary site closure processes.

In order to be able to efficiently see inventory at all locations, we developed our first ever inventory cube (a highly complex program utilizing 3D spreadsheets) and now have the ability to measure ourselves against relevant metrics used by external customers. We created complimentary vision based on SQDIC+P, which stands for Safety, Quality, Delivery, Inventory, Cost and People. It’s important that our people are central to this vision as they are the strength of the organization.

We have also made progress in solving challenges at the Venlo (Netherlands) location, which we are continuing to improve every day. Things are going very closely to plan and we’ve kept costs below budget for the first half of the year.

Could you please explain the changes as well as the new structure?

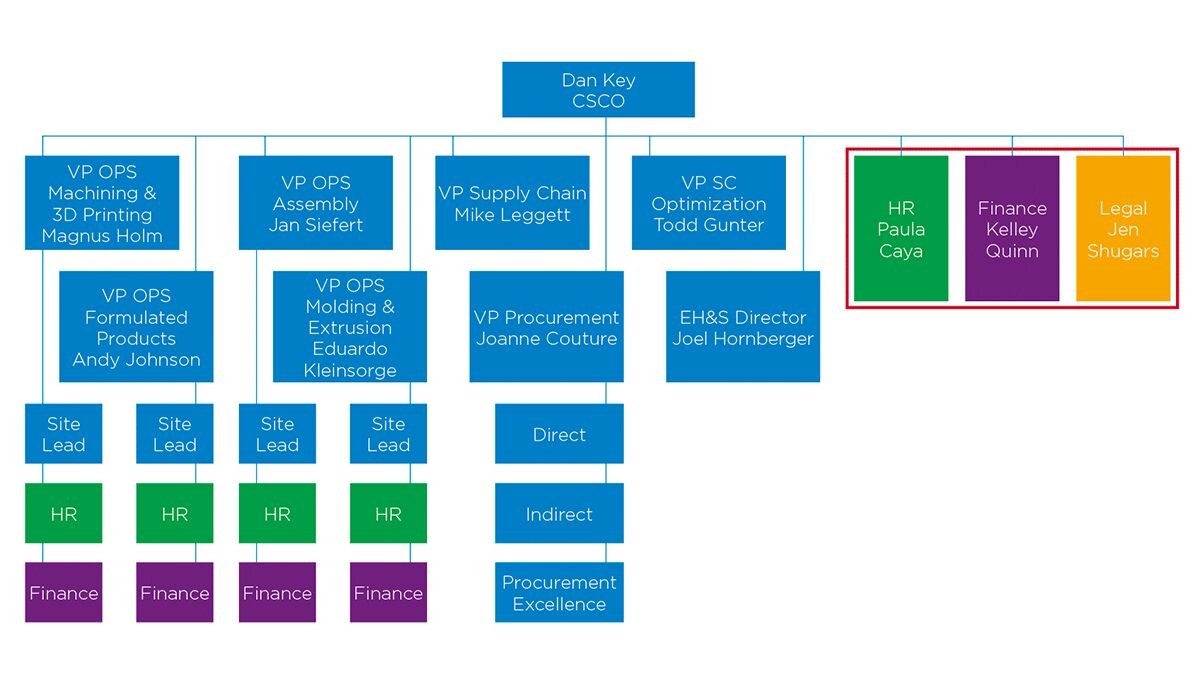

DK: The new supply chain is divided into two major areas: the management of the manufacturing and the functional support to the manufacturing teams. Manufacturing sites are managed based on five specific manufacturing technologies: Wellspect-related technologies, Equipment Assembly, Formulated Products, Machining and 3D Printing, and Extrusion & Molding. We arranged manufacturing into technologies in order to facilitate sharing best practices, use common equipment and processes, and look or network synergies that give us an advantage over other manufacturers. The benefits in this structure include lower costs, better service due to location, and significant business continuity due to our global breadth of manufacturing. The functional teams are designed to support the manufacturing divisions and our customers. We have functional groups for Supply Chain (planning, warehousing, logistics, and distribution), Procurement (indirect and direct), Project Management, Environmental, Health & Safety (EH&S), Human Resources (HR), Legal and Finance.